Torsion Springs

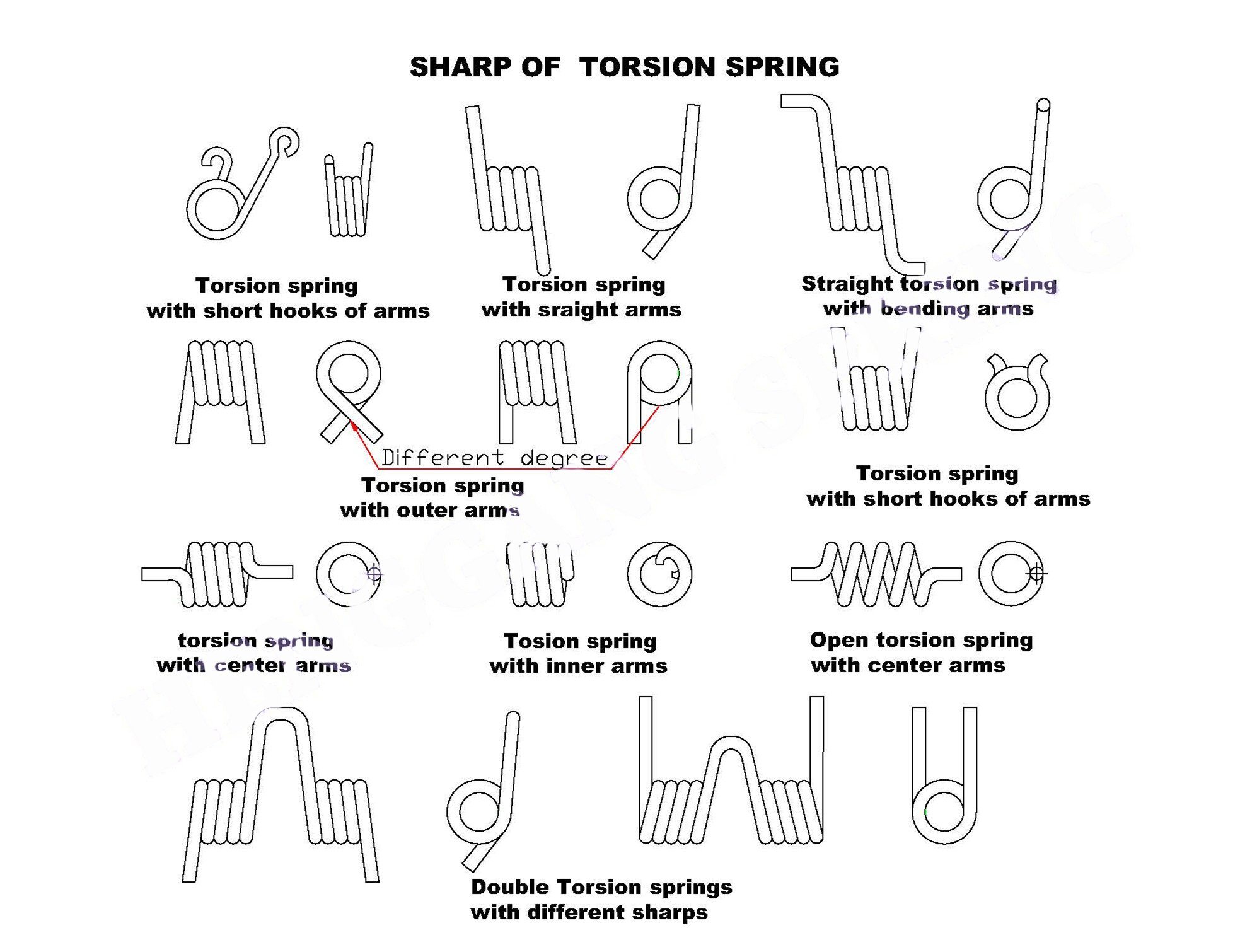

Torsion springs are used to apply a torque or store rotational energy. The two most common types of torsion springs are single and double bodied torsion springs. Torsion springs can be found in ratchets, counterbalance mechanisms, motor pump assembly, and various types of machine components.

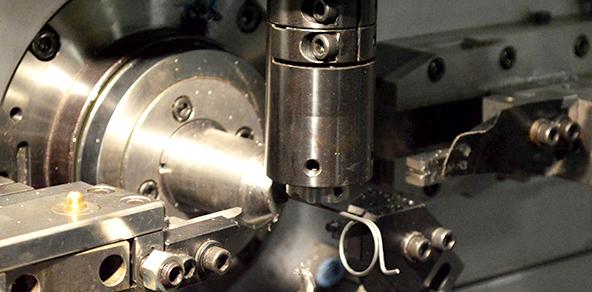

As a leader in niche market springs, we have the experience and background needed to build unconventional springs made from exotic materials in small or large volumes.

The two types of torsion springs are single and double bodied springs. Most torsion springs are designed with round wire due to costs of rectangular material.

When designing a torsion spring, we consider the type of wire to be used, temperature and atmosphere it is to be used in, load requirements, and any other special needs of your project.

All these factors determine the final build of the torsion spring. Springs can be manufactured using a wide range of materials such as common steels and alloys like stainless and music, as well as exotic materials such as Inconel, Monel, Hastelloy, and Titanium.

Compression Spring Materials

- Stainless 302, 316, 17-7

- Music

- Beryllium Copper

- Brass

- Chrome Silicon, Vanadium

- Elgiloy

- Hastelloy

- Hard Drawn

- Inconel

- Monel

- Oil Tempered

- Phospher Bronze

- Titanium

- Tungsten

In designing torsion springs

It is not just the numbers that add up to a good plan, it’s also the knowledge and experience we offer in manufacturing our products. We are ready to deliver custom torsion springs to suit any conventional or unique application. Contact us directly to learn more about our services.